Looking to partner with an OEM toy manufacturer in China? Just like structuring a comprehensive assignment, this article is organized into clear sections—introduction, body, and conclusion—to ensure you understand the essay’s purpose and can easily follow each step. Similarly, essay writing is a structured process that involves drafting, organizing ideas, and using tools to enhance clarity and effectiveness. This article will show you how to choose the right manufacturer, leverage cost advantages, and ensure high standards. With OEM toy manufacturer China as the key word, this article will explain key strategies for effective communication, overcoming challenges, and achieving market success.

Introduction to the Toy Industry

The toy industry holds a significant role in society, shaping the way children learn, play, and develop essential skills. As technological advancements continue to influence every aspect of our lives, the toy sector has evolved to incorporate innovative features such as AI technology and interactive learning experiences. Educational toys, in particular, have gained prominence, offering children opportunities to engage in meaningful play that supports cognitive growth and creativity. In this context, understanding the toy industry requires a comprehensive analysis of its history, current trends, and future prospects. A well-structured essay on this topic would begin with a clear thesis statement, followed by an introduction that sets the stage for a deeper exploration of the industry’s key aspects. For instance, examining how technology has transformed traditional toys into smart, connected devices provides valuable insight into the industry’s ongoing evolution. Ultimately, a thorough understanding of the toy industry’s dynamics is essential for anyone seeking to succeed in this vibrant and ever-changing field.

Key Takeaways

- Understanding OEM toy manufacturing is vital for businesses aiming to differentiate themselves while minimizing manufacturing costs and risks.

- Partnering with Chinese OEM manufacturers offers competitive pricing, rapid production, and reliable shipping, positioning toy companies for success.

- Effective communication and quality control are essential for overcoming challenges in OEM toy manufacturing, ensuring high product standards and smooth collaborations.

Understanding OEM Toy Manufacturing

OEM (Original Equipment Manufacturer) toy manufacturing allows toy companies to produce toys that meet their specific designs and branding while leveraging established manufacturing practices. This model is particularly beneficial for businesses that want to maintain a unique identity in a competitive market without investing heavily in manufacturing infrastructure.

With the toy industry expected to see massive growth by 2028, understanding the nuances of OEM toy manufacturing becomes crucial. The industry is influenced by factors like e-commerce, social media trends, and gaming influencers, all of which shape consumer preferences. China, as a leading exporter, supplies toys to many other countries, highlighting its global reach and dominance in the international supply chain. Determining the type of toy product and its target audience is crucial for successful sales and market positioning. Students in business and engineering programs often study OEM toy manufacturing as part of their curriculum to better understand these industry dynamics.

Mastering these fundamentals helps toy businesses navigate OEM manufacturing complexities, align strategies with market demands, and foster sustainable growth and innovation. Organizing information into clear paragraphs is essential to enhance understanding of complex manufacturing concepts.

Market Research and Analysis for OEM Toy Projects

Market research and analysis are essential steps in the writing process for any successful OEM toy project. To develop toys that resonate with your target audience, it’s crucial to gather and interpret data on consumer preferences, current trends, and technological advancements. Statistics and specific statistic measures are used to interpret market trends and consumer preferences, helping companies make informed decisions. For example, the growing popularity of educational toys and the integration of AI technology are shaping the expectations of both children and parents. By conducting thorough research, toy companies can identify gaps in the market, generate innovative ideas, and understand which features or themes are most likely to drive success.

Effective market analysis also involves studying competitors, evaluating the feasibility of new product ideas, and forecasting demand for different types of toys. It is important to explain research findings in clear sentences so the reader can easily understand the implications for OEM toy projects. This process helps companies stay ahead of trends and ensures that their products meet the evolving needs of their audience. By leveraging data-driven insights and continuously monitoring the market, toy businesses can develop products that not only capture attention but also deliver lasting value, supporting long-term growth and success.

Business Planning and Strategy for OEM Toy Ventures

Developing a successful OEM toy venture begins with a strategic business plan that outlines clear objectives and actionable steps. The writing process for such a plan should start with a strong thesis statement that defines the company’s mission and unique value proposition. Conducting thorough research and analyzing data on market trends, consumer preferences, and competitor offerings are essential for identifying opportunities and potential challenges. For example, understanding the exponential distribution of demand can help a toy company optimize inventory management and streamline the distribution process, ensuring products reach customers efficiently.

Leveraging social media platforms and e-commerce channels is another critical aspect of modern business strategy, enabling companies to connect with a broader audience and build brand recognition. By using statistics and data analysis, businesses can identify patterns in consumer behavior and tailor their marketing efforts accordingly. Throughout the planning process, it is important to provide context for each decision, support claims with relevant data, and ensure that the overall strategy aligns with the company’s long-term goals. A well-written business plan not only guides the company’s growth but also serves as a valuable tool for securing investment and fostering success in the competitive toy industry.

Statistical Analysis in Toy Manufacturing

Statistical analysis plays a significant role in the toy manufacturing industry, enabling companies to make data-driven decisions that enhance both efficiency and market success. By applying statistical distributions, such as the exponential distribution, a toy company can analyze sales data, customer demographics, and product demand to better understand consumer behavior. For instance, using these analytical tools allows manufacturers to determine the optimal point for launching a new toy, set competitive pricing, and forecast inventory needs based on historical distribution patterns.

This type of analysis is essential for identifying trends and pinpointing areas where improvements can be made in the manufacturing process. For example, by examining data on production times and defect rates, companies can implement targeted changes that reduce waste and increase overall efficiency. Understanding the significance of statistical analysis helps toy manufacturers stay competitive, adapt to changing market conditions, and deliver products that meet the evolving needs of their audience. Ultimately, leveraging statistical techniques empowers toy companies to optimize their operations and achieve greater success in the global toy market.

Benefits of Partnering with Chinese OEM Toy Manufacturers

Collaborating with Chinese OEM toy manufacturers provides several advantages that can significantly improve a toy company’s profitability. One of the most compelling benefits is competitive pricing. Lower labor costs, economies of scale, and efficient supply chain management in China contribute to cost-effectiveness, enabling businesses to achieve greater profit margins.

Beyond cost savings, Chinese manufacturers are known for:

- Rapid production of trending products.

- Rapid prototyping capabilities that allow quick transitions from concept to market-ready products, keeping toy companies ahead of the curve.

- Reliable shipping services that support access to vast markets and ensure timely distribution of products.

The combination of cost advantages, market access, and technological innovation by Chinese OEM toy manufacturers positions businesses for success in a competitive market. Such benefits make China an appealing destination for toy companies aiming to scale efficiently and effectively.

Top OEM Toy Manufacturers in China

China is home to several top-tier OEM toy manufacturers, each specializing in different types of toys. Guangdong province Alpha Animation and Culture Co., Ltd., located in Guangzhou, Guangdong province, stands out for its action figures and educational toys based on popular animated series. This company’s expertise in combining entertainment and education makes it a preferred partner for many toy businesses.

Another notable manufacturer is Yixing Great Plastic Products Co., Ltd., based in Yixing, Jiangsu province. Their company address reflects their strong presence in the region, and they specialize in plastic and rubber toys, particularly balls. With ISO 9001 certification since 2005, they exemplify high standards in production and quality control.

Woodfield Toys Ltd., with its address in Ningbo, Zhejiang province, focuses on wooden toys and boasts a design team capable of creating 30 new products each month, showcasing their innovation and creativity.

Wecare Toys Co., Ltd., located in Shantou, Guangdong province, and Cangnan Huaou Crafts & Gifts Co., Ltd., based in Cangnan, Zhejiang province, are also significant players. Wecare Toys produces metal construction toys and educational games and has passed various safety audits, including EN71 and ASTM. Cangnan Huaou is known for educational toys, crafts, and gifts, particularly paper-based products like board games and puzzles.

These companies’ specializations, along with their company addresses and proven track records, make them reliable partners in the toy company manufacturing landscape. The diversity of the Chinese OEM toy manufacturing industry is represented by the wide range of specialties and product types offered by these companies.

Top Chinese Cities for Wholesale Toy Purchasing

When it comes to sourcing toys at scale, understanding the landscape of China’s wholesale markets is essential for any toy business. Guangdong province stands out as a leading region, with cities like Chenghai and Dongguan renowned for their extensive selection of educational toys and other products. These cities offer a diverse range of toys at competitive prices, making them attractive destinations for buyers seeking quality and variety. Navigating these markets requires a solid grasp of the various aspects of the toy business, including production, distribution, and marketing strategies.

To provide context for businesses and individuals engaging with Chinese manufacturers, it is important to summarize the key points of the toy industry in these regions. Knowledge of local practices, negotiation techniques, and supply chain logistics can greatly enhance the purchasing experience. Additionally, understanding proper citation style and referencing is crucial in academic and professional communications, ensuring that all sources and partnerships are accurately represented. In conclusion, a well-informed approach to wholesale toy purchasing in China’s top cities can open doors to new opportunities and long-term success in the global toy market.

Key Factors to Consider When Choosing an OEM Toy Manufacturer

Selecting the right OEM toy manufacturer is a crucial decision that can influence the success of your toy business. Key factors to consider include:

- Production capabilities

- Quality control measures

- Certifications

- Communication skills

As a reader, you should approach the process of evaluating potential manufacturers as you would a detailed assignment—gathering comprehensive information, breaking down your research into clear sections, and organizing your findings to make an informed decision.

State-of-the-art quality control processes have been increasingly adopted by Chinese manufacturers, enhancing reliability and establishing trust in the world products.

Inspecting potential manufacturers’ facilities firsthand offers valuable data knowledge insights into their production capabilities and working conditions for readers. An introduction that communicates in the preferred language of employees can reduce barriers and enhance engagement, fostering a more collaborative write focus environment.

An in-depth understanding of China’s toy manufacturing landscape is crucial for navigating sourcing and production complexities. A comprehensive supply chain strategy helps mitigate risks like material shortages and production delays, ensuring a smoother manufacturing process.

The Process of Working with Chinese OEM Toy Manufacturers

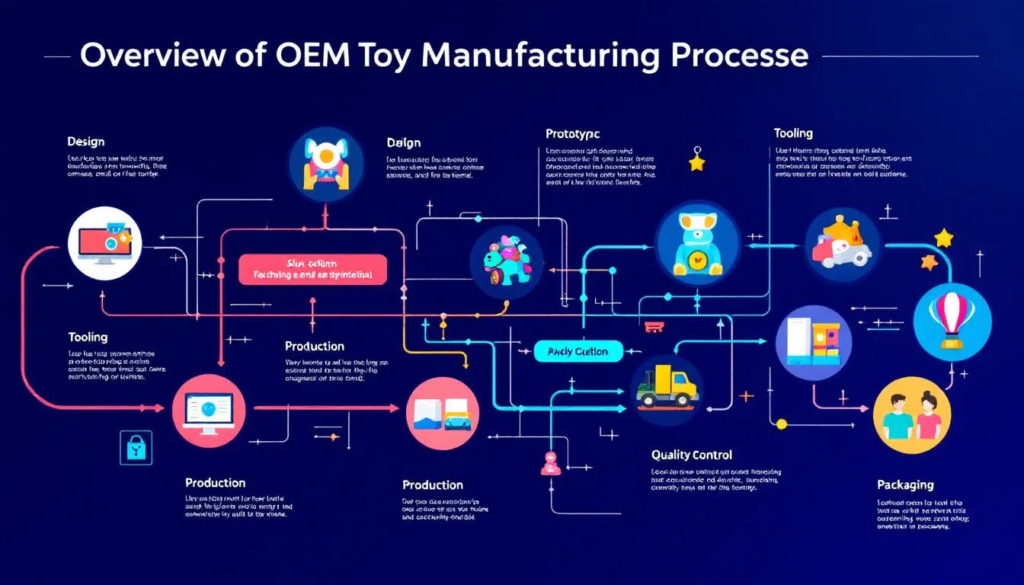

Working with Chinese OEM toy manufacturers involves a step-by-step process:

- Initial contact with manufacturers.

- The EJET sourcing agency acts as an intermediary between buyers and Chinese sellers.

- EJET facilitates initial contact.

- EJET provides professional strategies based on business requirements.

- Scaling production following initial stages.

Chinese manufacturers are known for their ability to scale production rapidly, accommodating fluctuations in demand effectively. The extensive network of suppliers in China ensures a reliable and efficient sourcing process for raw material, crucial for maintaining production timelines.

Instant communication tools can greatly improve problem-solving and operational efficiency on the factory floor. Mobile communication solutions ensure timely updates for all employees, especially during crises, enhancing manufacturing efficiency.

Chinese Toy Market and Regulations

The Chinese toy market plays a significant role in the global toy industry, representing one of the largest and most dynamic markets in the world. For companies aiming to manufacture or distribute toys in China, understanding the regulatory landscape is essential. Chinese regulations cover a wide range of aspects, from the safety of raw materials to the design and labeling of toys for different age groups. Compliance with these standards is crucial to avoid penalties, product recalls, or barriers to market entry.

In addition to regulatory compliance, companies must also navigate the unique distribution channels and marketing strategies that define the Chinese market. Social media platforms are particularly influential, providing powerful tools for reaching consumers and building brand awareness. By understanding the expectations of Chinese consumers and adapting to local regulations and distribution methods, toy companies can successfully establish and grow their presence in this important market.

Industry Associations and Certifications in the Chinese Toy Sector

Industry associations and certifications play a significant role in shaping the standards and practices of the Chinese toy sector. Organizations such as the China Toy & Juvenile Products Association provide essential support to manufacturers by promoting best practices, facilitating industry collaboration, and advocating for regulatory compliance. Certifications like ISO 9001 for quality management and ISO 14001 for environmental sustainability are crucial indicators of a company’s commitment to excellence and responsible production.

In a well-structured essay, a body paragraph discussing these associations and certifications would provide context for their importance, explaining how they support the main points of quality assurance and industry credibility. For instance, as climate change becomes an increasingly pressing issue, the adoption of environmentally friendly practices and certifications demonstrates a company’s dedication to sustainability. This discussion not only enhances understanding of the toy industry’s regulatory landscape but also highlights the significance of maintaining high standards in product safety and environmental stewardship. Ultimately, industry associations and certifications are essential for building trust with consumers and supporting the long-term success of the toy sector.

Supply Chain Management and Logistics in Toy Manufacturing

Efficient supply chain management and logistics are vital for ensuring that toys reach customers on time and in optimal condition. This process involves coordinating with suppliers, managing production schedules, and optimizing transportation and storage. Probability models can be used to forecast supply chain disruptions and optimize logistics planning, helping companies anticipate and mitigate potential risks. The use of advanced technology, such as data analytics and AI, can greatly enhance supply chain operations. For example, predictive analytics can help forecast demand, allowing companies to adjust production and inventory levels proactively.

Automated warehouse systems and real-time tracking solutions further streamline logistics, reducing costs and improving delivery speed. It’s also important for toy companies to consider the environmental impact of their supply chain, such as sourcing sustainable raw materials and minimizing the carbon footprint of transportation. By investing in robust supply chain management and leveraging technology, toy businesses can maintain a competitive edge while meeting the expectations of today’s environmentally conscious consumers.

Toy Design and Development for OEM Projects

The process of toy design and development for OEM projects is both an art and a science, requiring a deep understanding of the target audience and current market trends. Successful toy companies begin with thorough research, gathering ideas and feedback to inform the initial concept. Designers then use tools like CAD software and 3D printing to create prototypes, allowing for rapid iteration and testing. Having clear, written specifications at this stage is crucial, as they guide the design and development process and ensure all requirements are met.

Throughout this process, it’s essential to balance creativity with practicality—ensuring that toys are not only engaging and fun but also safe, durable, and compliant with relevant standards. Educational value is another key consideration, as many parents seek toys that support learning in areas like science, art, and social skills. By focusing on both entertainment and educational outcomes, toy designers can develop products that appeal to a wide audience and drive success in the competitive OEM toy market.

Toy Packaging and Shipping Considerations

Toy packaging and shipping are critical aspects of the manufacturing process that directly impact product safety and customer satisfaction. Effective packaging must protect toys during transit, provide clear instructions, and comply with regulatory requirements, including proper labeling and safety warnings. The choice of packaging materials also reflects a company’s commitment to sustainability, with many businesses now opting for eco-friendly options to reduce environmental impact.

The shipping process involves selecting reliable carriers, managing inventory, and using technology such as barcode scanning and GPS tracking to monitor orders and ensure timely delivery. By prioritizing robust packaging and efficient shipping logistics, toy companies can safeguard their products, enhance the customer experience, and build a strong, trustworthy brand in the marketplace.

Common Challenges and Solutions in OEM Toy Manufacturing

OEM toy manufacturing is not without its challenges. Cultural differences can lead to misunderstandings between manufacturers and clients, impacting project timelines and outcomes. Logistical challenges, such as shipping delays and customs regulations, often complicate the timely delivery of toy products.

Clear communication channels and cultural understanding are key to addressing these challenges. Effective communication and cultural awareness help mitigate risks, ensuring smoother collaborations and better project outcomes.

Case Studies: Successful Partnerships with Chinese OEM Toy Manufacturers

Weijun Toys offers compelling examples of successful partnerships with Chinese OEM toy manufacturers. They have effectively turned various creative concepts into mass-produced products, showcasing their adaptability and innovation. For instance, their collaboration with Hachette Book Group to create Disney-themed figure collections starting in 2019 illustrates their capability to handle high-profile projects.

Another notable partnership is with Paladone, where Weijun Toys produced various Harry Potter-themed collectibles, including keychains and blind boxes. They also worked with Thumbs Up to create a range of Pusheen-themed products, including collectibles and mini figurines.

Weijun Toys’ collaboration with Commansi to develop a series of figures based on the popular Peppa Pig theme, and their work with Mattel to produce licensed figures from the Barbie and Hot Wheels series, further highlight their success in OEM toy manufacturing. These partnerships demonstrate the potential for successful collaborations and the positive outcomes that can be achieved.

Tips for Effective Communication with OEM Toy Manufacturers

Effective communication is vital when working with OEM toy manufacturers. Key aspects include:

- Manufacturers need to provide timely responses.

- Maintaining various channels for updates ensures smooth collaboration.

- Establishing multiple channels for updates can enhance communication and keep all parties informed.

Overcoming communication barriers, often exacerbated by language differences, is essential for effective collaboration. To provide context, summarize main points, and clearly discuss ideas can bridge gaps and facilitate better cooperation, especially when presenting an argument and considering the interpretation of the information. Structuring effective communication with manufacturers is much like organizing a body paragraph in an essay: starting with a clear topic sentence to introduce the main idea, and ending with a strong concluding sentence to reinforce the key point and ensure cohesion. Similarly, it is important to describe these learning strategies effectively and include analysis of these writing approaches to point out key insights about words that represent key concepts in essay form, including body paragraphs. This idea can enhance understanding and promote effective teamwork through discussion, particularly in the context of climate change, providing inspiration for innovative solutions to claim better outcomes. The significance of these strategies cannot be overstated.

Ensuring Quality Control in OEM Toy Production

Quality control in OEM toy production is vital for maintaining product safety and reliability. Adhering to international safety standards, such as ASTM F963 and EN71, is essential to avoid recalls and ensure compliance with safety regulations.

Regular third-party inspections and continuous testing during production stages help identify quality issues early, maintaining high product standards. Regular audits of manufacturing processes significantly enhance compliance with established quality protocols.

Pre-production planning with detailed product specifications prioritizing safety standards is crucial for successful OEM toy manufacturing. These practices ensure that the final products meet the highest quality and safety standards, building trust with consumers.

Leveraging Technological Advancements in Toy Manufacturing

Technological advancements significantly transform toy manufacturing in China. Investments in AI technology enhance product innovation and streamline processes, leading to more efficient production.

Collaborating with tech companies in China improves the quality of electronic toys and gaming products, meeting the growing demand for tech-integrated toys. Automation in manufacturing significantly reduces production costs, making toys more affordable and accessible.

Monitoring market trends and technological advancements helps manufacturers innovate and adapt to consumer demands, ensuring their products remain competitive and relevant.

E-Commerce and Online Sales Strategies for OEM Toys

The rapid growth of e-commerce has revolutionized the way OEM toys are marketed and sold, offering toy companies unprecedented access to a global audience. By utilizing social media platforms, online marketplaces, and dedicated e-commerce websites, OEM toy manufacturers can showcase their educational toys and other products to a diverse and engaged audience. Crafting a clear thesis statement, such as “Our OEM toys provide innovative, high-quality learning experiences for children worldwide,” helps guide the writing process for all online content, ensuring a consistent and compelling brand message.

Incorporating SEO strategies—like using keywords such as “toy company,” “educational toys,” and “social media platforms”—can significantly boost online visibility and attract more potential customers. The process of building a strong online presence also involves providing excellent customer support through live chat, email, and responsive service, which helps foster trust and loyalty among buyers. By focusing on these e-commerce strategies, OEM toy companies can expand their reach, increase sales, and establish themselves as leaders in the digital marketplace.

Trade Shows and Industry Events in the Toy Sector

Trade shows and industry events are essential for staying connected and competitive in the toy sector. These gatherings provide a unique opportunity for manufacturers, suppliers, and buyers to learn about the latest technological advancements, network with industry peers, and showcase new products to a global audience. The Guangdong province in China, recognized as a major hub for toy manufacturing, regularly hosts world-class trade shows that attract participants from across the globe.

Attending these events allows OEM toy companies to gain valuable insights into emerging trends, discover innovative technologies, and establish relationships with potential partners. It is also an opportunity to demonstrate a commitment to quality, safety, and sustainability—factors that are increasingly important in the toy industry. By participating in trade shows and industry events, companies can learn from industry leaders, stay ahead of the competition, and position themselves for long-term success in the ever-evolving world of toy manufacturing.

Industry Trends and Predictions for OEM Toy Manufacturing

The OEM toy manufacturing industry is experiencing rapid change, driven by evolving consumer preferences, technological advancements, and global market shifts. One of the most prominent trends is the rising demand for educational toys that foster learning and cognitive development. Toy companies that focus on creating interactive, high-quality products designed to support children’s learning are expected to thrive in this environment.

Sustainability is another key focus, with both consumers and manufacturers placing greater emphasis on eco-friendly materials and responsible production processes. Companies that adopt green practices and minimize waste are likely to gain a competitive edge. Additionally, the integration of AI technology and other digital innovations is transforming the way toys are designed and experienced, leading to more engaging and sophisticated products. By staying informed about these trends and predictions, OEM toy manufacturers can adapt their strategies, embrace new technologies, and continue to meet the needs of a dynamic and growing market.

Staying Competitive in the Toy Industry

Staying competitive in the toy industry requires a proactive approach to innovation and adaptability. A strong topic sentence for this discussion might emphasize the importance of embracing technological advancements and responding to evolving consumer preferences. Businesses must invest in research and development to create products that resonate with today’s market, such as educational toys that support learning and development. Analyzing data and statistics on consumer trends allows companies to develop targeted strategies and anticipate shifts in demand.

For example, exploring the influence of the American dream on toy purchasing decisions can provide valuable insights into cultural and social factors that drive consumer behavior. Similarly, understanding the role of social media platforms in shaping public opinion and marketing strategies is essential for reaching and engaging modern audiences. By fostering a culture of continuous learning and innovation, toy companies can develop products and campaigns that stand out in a crowded marketplace. In summary, a comprehensive analysis of industry trends, supported by robust research and data interpretation, is key to achieving lasting success in the dynamic world of toys.

Marketing Your OEM-Manufactured Toys

Marketing OEM-manufactured toys requires a well-crafted brand identity, including a memorable logo and coherent color scheme, to stand out in a competitive market. Social media platforms like Instagram and TikTok can significantly enhance brand engagement and community interaction for toy brands.

Collaborating with toy reviewers and influencers boosts brand credibility and attracts new customers. Offering free samples, free consultations, or free resources can be an effective marketing strategy to attract and engage potential customers. Developing educational AI toys that teach coding and problem-solving to children emphasizes early tech engagement and broadens your market.

Customer Service and Support in OEM Toy Partnerships

Outstanding customer service and support are essential for building successful OEM toy partnerships. Buyers and partners expect prompt communication, effective problem-solving, and a steadfast commitment to quality and safety throughout the collaboration. Providing comprehensive support—including product training, maintenance, and repair services—ensures that the needs of customers and partners are consistently met.

Leveraging digital tools such as social media platforms and online support portals can streamline communication and make it easier to address issues quickly. By prioritizing customer satisfaction and support, OEM toy companies foster trust, encourage repeat business, and build long-term relationships that drive ongoing success. In conclusion, by focusing on exceptional customer service, OEM toy manufacturers can differentiate themselves in a competitive market and achieve lasting business growth.

Summary

This section summarizes the key strategies and benefits discussed in the article.

In conclusion, partnering with Chinese OEM toy manufacturers offers numerous benefits, from cost-effectiveness and rapid prototyping to reliable shipping and technological innovation. By understanding the process, addressing challenges, and leveraging advancements, toy companies can thrive in a competitive market.

The potential for growth and success is immense. By following the strategies discussed in this guide, toy businesses can navigate the complexities of OEM toy manufacturing and achieve their goals. Embrace these opportunities and watch your toy company soar to new heights.

Frequently Asked Questions

What are the benefits of partnering with Chinese OEM toy manufacturers?

Partnering with Chinese OEM toy manufacturers offers great benefits like competitive pricing, quick prototyping, dependable shipping, and access to the latest tech innovations. It’s a smart move if you want to enhance your toy business!

How do I choose the right OEM toy manufacturer?

To choose the right OEM toy manufacturer, focus on their production capabilities, quality control measures, and communication skills. Don’t hesitate to visit their facilities and ensure your supply chain strategy is solid!

What challenges are common in OEM toy manufacturing?

OEM toy manufacturing often faces challenges like cultural differences, logistical issues, and communication barriers. Tackling these through clear communication and cultural understanding can significantly ease the process.

How can I ensure quality control in OEM toy production?

To ensure quality control in OEM toy production, make sure to follow international safety standards, conduct regular third-party inspections, and carry out continuous testing. Detailed pre-production planning with clear product specifications is essential for success.

What technological advancements are impacting toy manufacturing in China?

Technological advancements like AI and automation are transforming toy manufacturing in China by boosting product innovation and cutting production costs. This means higher quality electronic toys and gaming products are coming your way!